If you’ve spent any time in New York City in 2017, you know that the subway system is currently a hot mess - and I’m not talking just about its sweltering platforms. With more than 70,000 subway delays per month (up from 28,000 just five years ago), we New York city dwellers, like our subway, are at a breaking point.

The New York Times reports that by far the biggest issue causing delays is overcrowding. But according to New York State, the fastest a new subway car can be built is three years, and on top of that, adding more cars doesn’t do much to fix the underlying issue that will only grow when adding more cars: inefficient maintenance.

In fact, most of the MTA’s six-point plan announced in May 2017, even though it does mention maintenance several times, does nothing to bring the New York City subway into the modern, data-driven era the way it should.

The Problem with “Preventative”

Nearly all of the mentions of maintenance in the six-point plan talk about expanding a preventative maintenance program, not moving toward a predictive one. For example:

- “The MTA is focused on reducing average response time of its emergency crews to 15 minutes or less.”

- “This new initiative will add additional inspectors and redeploy resources to ensure every car receives pre-service inspection before a car ever leaves the rail yard to reduce the likelihood of a mid-trip failure.”

- “The MTA is … doubling its ultrasonic testing from once a month to twice monthly in order to more efficiently detect track defects.”

Instead of lowering response time, the focus should be on not needing emergency response. And instead of increased preventative testing, the focus should be real time, since the 24-hour-a-day grind means breakdowns can certainly still happen in between those twice monthly tests.

So while “preventative” is a nice word and it sounds well and good, the difference between predictive and preventative maintenance is astounding both in terms of cost, resources, and - most importantly - downtime.

Yes, overcrowding is an issue. But inefficient maintenance will continue to plague the MTA, maybe more so after adding extra cars.

The Advantage of Predictive

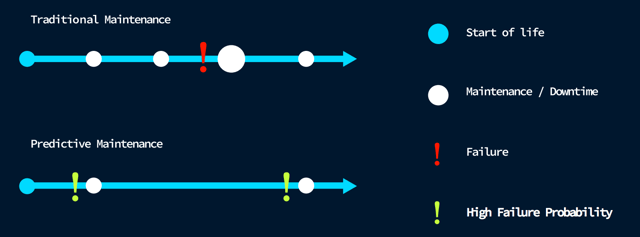

Predictive maintenance often allows for the detection of impending failures that could never be detected by human eyes - take, for example, imaging that looks for microcracks or that detects vibrations and sounds, even while trains, tracks, escalators, etc., are in use. With predictive maintenance, downtime and repairs are directly tied to likely failure, minimizing cost (less downtime, less labor time, less chance of unexpected failure) and maximizing asset life.

By contrast, traditional maintenance techniques (run-to-failure, preventative, or some combination of the two) inevitably mean unexpected repair, which leads to longer downtime on top of unnecessary downtime due to regular inspection. Due to a lack of a complete picture surrounding the state of a given asset, traditional maintenance presents a slew of issues that contribute to both the breakdown of equipment and rising costs - the very things maintenance efforts are in place to prevent.

Traditional maintenance (including preventative) means unexpected repair on top of downtime due to regular inspection.

Of course, it’s not such a binary question as traditional versus or against predictive maintenance, as even with a predictive maintenance strategy, some traditional inspections may be performed - for example, after a storm or major event. But in general, the move toward predictive maintenance - even partially - has huge associated cost savings and paves the way toward the future of commuter travel.

IoT, STAT

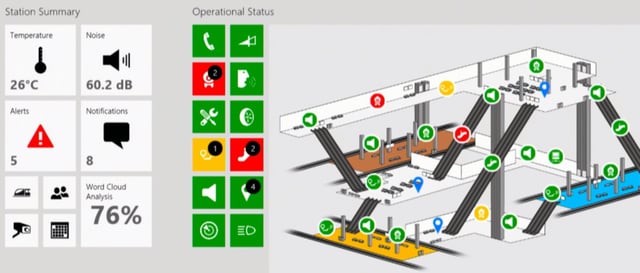

Opening in 1890, the London Underground is the oldest subway system in the world. But back in 2014, they committed to improvements by way of the Internet of Things (IoT). IoT is the essential component to a comprehensive predictive maintenance strategy - it allows Transport for London to detect abnormalities not only on tracks or trains themselves, but even on escalators and loudspeakers to keep the entire system running smoothly. And it's been reported that these changes on the Victoria line alone save £600,000 every year on top of reducing customer hours lost on delays by 58 percent.

Transport for London uses IoT to detect abnormalities throughout the London Underground, from tracks to loudspeakers.

Yes, transforming the New York City subway system with IoT would be costly. But it’s the right solution. If there’s going to be any hope of relief anytime soon, the MTA needs to take large strides toward a long-term solution, not small (yet still expensive) steps.

The goals are lofty, but modernizing the New York City subway with IoT and predictive maintenance is the only way to make big, impactful changes. With this kind of modernization, the MTA could then ultimately tackle the arguably larger problem of overcrowding more effectively. And then what would we New Yorkers have to complain about?