Equipment reliability is crucial for manufacturers, ensuring responsible, safe, and consistent product production. Regular maintenance is key to mitigate unplanned downtime and ensure safe, continuous operation.

But finding the right time for maintenance is a challenge in balancing operational and cost objectives. In many industries, maintenance is either reactive or driven by excessive time-based preventative routines, both of which are costly, erode asset performance, and lower operational efficiency, costing billions each year.

Time-based preventative maintenance approaches and reactive fire fighting have been two default strategies that no longer need to be the norm. Using AI and machine learning, manufacturers can refine their maintenance tactics by leveraging service history and equipment attributes. Techniques including survival analysis transform static time-based maintenance schedules into tailored plans that reflect and react to the true risk of mechanical failure by asset.

A Simple Solution With Dataiku

It’s true that predictive maintenance, despite being a catchy buzzword, is not a cure-all. But with the right people, the right strategy, the right understanding of your data, and a reasonable plan for how to scale, predictive maintenance can become the most valuable and powerful asset in your toolkit.

And with Dataiku, it’s never been simpler to get started. With our predictive maintenance solution, organizations quickly turn vast volumes of maintenance history into optimized maintenance plans. And thanks to common performance metrics like mean time between failures (MTBF), mean time to repair (MTTR), and task paretos, reliability engineers can easily explore their fleet behaviors with descriptive analytics.

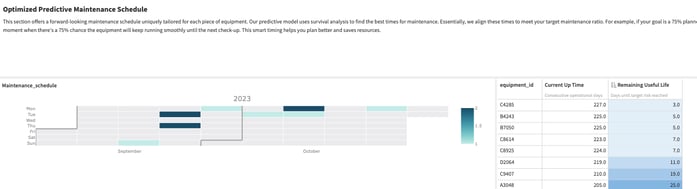

Machine learning algorithms provide remaining useful life information based on maintenance history, as well as a recommended maintenance schedule per asset, allowing service managers to adjust their strategies. Whether for internal equipment maintenance or improving customer service, the predictive maintenance solution, which can be installed right in your Dataiku instance, enables organizations to promptly revisit their manufacturing strategies.

Here are some of the solution’s key benefits:

- Leverage maintenance history data from your CMMS, EAM or other work management system.

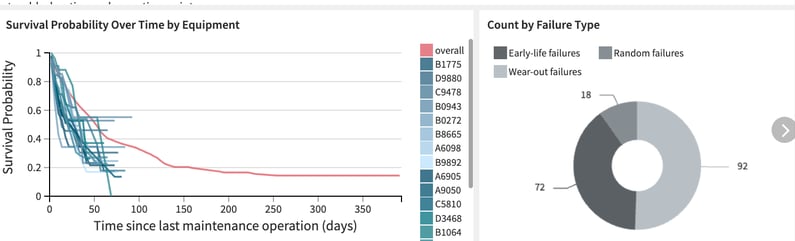

- Visualize descriptive insights including mean time between failure, remaining useful life and weibull distributions across your fleet.

- Create an optimized maintenance schedule based on your business goals by selecting your ideal unplanned maintenance ratio.

- For each asset, assess remaining useful life and ideal maintenance operation schedules, thanks to an explainable and transparent machine learning model.

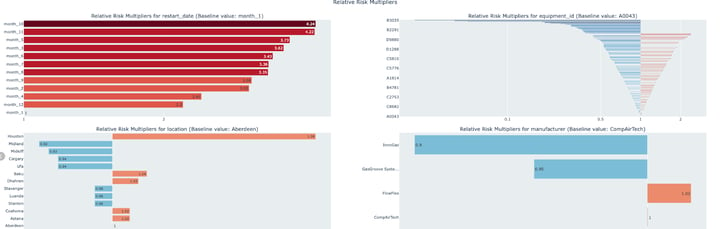

- Understand what’s driving unplanned maintenance by evaluating the impact of various attributes (such as geo location & asset age) on unplanned maintenance operations.

Predictive Maintenance Solution Features

Getting started with the predictive maintenance solution is as simple as its benefits are substantial. In just six steps, you can transform your equipment data from its raw state to a game changer for your business.

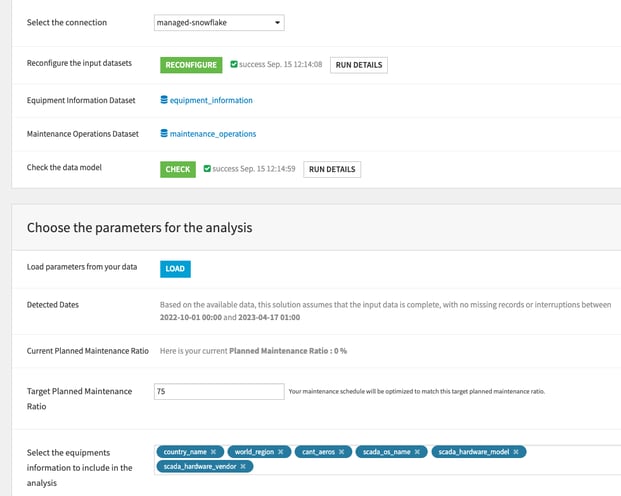

Define Planned vs Unplanned Maintenance Goals via the Dataiku Application

Easily ingest relevant data sources and define target planned maintenance ratio as well as attributes of interest.

Gain Insight Into Maintenance Activities & Performance Across a Fleet of Assets

Benefit from descriptive statistical analytics across your fleet to identify bad actors, recurring issues and trends.

Track Remaining Useful Life

Understand remaining useful life per asset using both your planned and unplanned maintenance activities.

Optimize Your Personnel & Fleet Through Tailored, Need-based, Planned Maintenance

Access a maintenance schedule designed to meet your planned/unplanned maintenance ratio target. Monitor achieved efficiency vs. ambition.

Determine What’s Driving Differences in Asset Performance

Benefit from full explainability of predictive models that expose the influence of different attributes on unplanned maintenance.

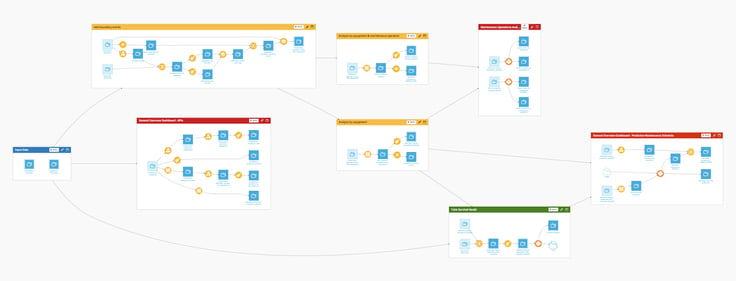

A Transparent Flow to Use, Adjust, and Scale

Leverage Dataiku’s unique explainable visual machine learning and data flow to tailor the solution to your needs and build extensions beyond using parametric data from your automation systems.