This is a blog post from our friends at Aimpoint Digital. Aimpoint Digital is a leading advanced analytics, data science, and engineering services firm that operates as the trusted advisor for companies looking to extract tangible value from data.

The Challenge

The holiday season is an exciting time for businesses and consumers alike as demand surges, new products are released, and sales abound. However, it can also be a stressful and challenging time for businesses, especially in recent years, because of difficulties in managing supply chain and labor issues and preventing stock-outs. In order to fulfill the increase in customer demand, businesses need to procure materials and inventory from their suppliers well ahead of time and carefully manage production, staffing, pricing, and marketing.

Figure 1: Resilient performance requires demand-driven planning and coordination across multiple operations.

While the peak season brings challenges and rewards every year, exploding volumes of sales data, expanding product lines, changing consumer behavior, and lingering effects of the global health crisis have created new hurdles. 40% of small businesses reported domestic supply delays this year, and over 60% face negative impacts.

External events like port congestion, overseas production slowdowns, and rising fuel costs continue to disrupt the supply of holiday season products and shipping — it’s clear that external information is now crucial to demand forecasting. And as consumer expectations change, businesses must forecast demand accurately across more channels (online and in-store) and execute timely deliveries. Because demand is at the heart of all business operations, improving demand forecasts in this complex environment is essential to ensuring smooth coordination across the business.

AI Methods for Demand Forecasting

The complexity of demand forecasting is increasing not only because of business challenges but also because of data challenges. These challenges include larger volumes of data, including noisy or incomplete data, or a lack of expertise to carry out complex pre-and post-processing steps.

Traditional time series models such as Autoregressive Integrated Moving Average (ARIMA) and Exponential Smoothing (ETS) may require extensive data processing and decreased performance compared to AI methods. In addition, AI methods may be more scalable and better handle highly multivariate time series data and external data.

While the best model and solution for demand forecasting depends on the specific use case, interest in AI-embedded methods has been growing because of their ability to handle complexity in time series forecasting and increase prediction performance.

An AI Case Study for Demand Forecasting

Challenge

Aimpoint Digital needed to create models that quickly generate accurate predictions of future peak season sales for a consumer product company, including related SKUs such as products and their accessories. These forecasts require easy integration into other workflows such as production, procurement, and inventory management.

The Approach

Aimpoint Digital ingested information into a scalable cloud-based platform. Using the time series forecast plugin in Dataiku, Aimpoint Digital leveraged multiple models including deep learning models (Feed Forward, Transformer, and DeepAR) and statistical time series (Seasonal Naïve, Trivial Identity, AutoARIMA) on multivariate times series to predict peak season demand.

Using peak season demand forecasts, we devised a strategy to maximize peak season profit by identifying the optimal (most cost effective) mixtures of raw material required to produce products to specifications and to satisfy all the forecasted demand using mathematical optimization and blended data.

Outcome Summary

AI-based demand forecasting models showed improved performance of up to 42%. Based on demand data, the production planning optimization model created a cost-reduction strategy to fulfill demand and increase peak season profits by over 60%. The optimization model also generated solutions 100x faster than spreadsheet-based methods, drastically reducing the manual effort needed to create 10,000 forecasts. Furthermore, we automated inventory management to send an email alert for upcoming inventory replenishment needs.

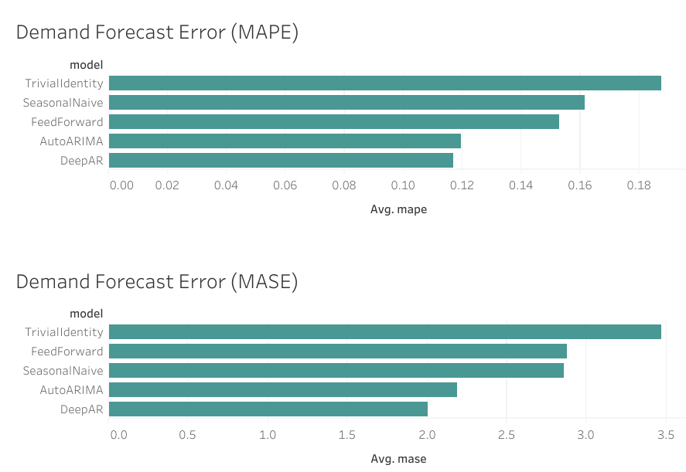

Figure 2: Model Performance – Among AI-based (Deep AR, Transformer, Feed Forward) and non-AI models (Seasonal Naive, Trivial Identity, AutoARIMA), the DeepAR AI model showed the best performance or lowest error as measured by MAPE (top) and MASE (bottom) error metrics.

The deep learning models (Feed Forward, Transformer, and DeepAR) showed improved performance in predicting peak season demand across a range of performance metrics. For example, there were reductions in mean absolute percentage error (MAPE) and mean absolute scaled error (MASE) of 35-40% (Figure 2) for a specific product compared to the previously used Trivial Identity or Seasonal Naïve models. In addition to the performance increase, by moving from spreadsheet-based methods to Dataiku, the client saw a dramatic reduction in the number of hours needed to generate forecasts, which enabled their team members to have the time to focus on other, high-value tasks.

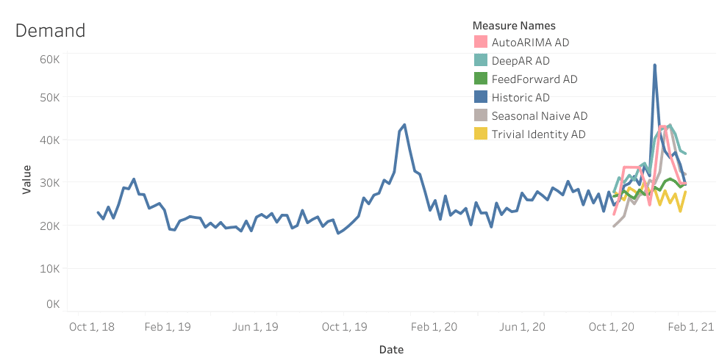

Figure 3: Predictions by Model (Testing) - Overlaid actual demand and demand predictions for a specific product or accessories for AI-based (Deep AR, Feed Forward) and non-AI models (Seasonal Naïve, Trivial Identity, AutoARIMA) show improved performance of AI models.

The demand forecasts of five different models for product demand over the peak season period varied considerably (Figure 3). The poor model performance scores seen in Figure 2 suggest that the Seasonal Naïve and Trivial Identity models (gray, yellow lines) underestimated product demand. In contrast, the DeepAR AI model (light blue) and AutoARIMA model (pink line) performed well.

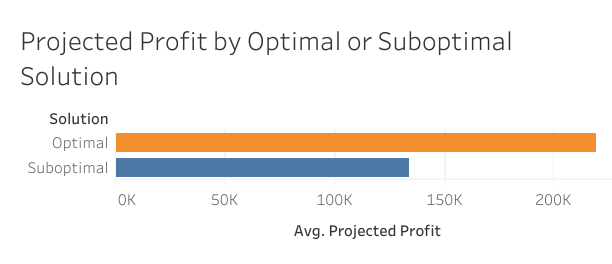

Figure 4: Forecasted demand for the peak season enabled optimized production planning, increasing projected profits by more than 60%.

Demand forecasts also improved production planning. From the demand forecasts generated, we built optimizations for a single line of business. The production optimization model used forecasted demand data as input to reduce costs by using optimized raw material selections. As a result, projected profits for the peak season increased by over 60% compared to a suboptimal raw material selection (Figure 4).

Improve Your Peak Season Demand Forecasting

The peak season is a rewarding time with high opportunities. With those rewards comes stress; however, there are ways to reduce that by having accurate demand forecasts.

Dataiku's managed AI platform enables you to use high-performance AI models for your peak season planning to create accurate demand forecasts across many products. Using these demand-driven supply chain methods will in the end reduce your costs and increase profits over the peak season.

At Aimpoint Digital, our data experts can help assess and implement a peak season demand forecasting model that provides actual business value.